[Autohome News] The 2018 Guangzhou Auto Show has officially kicked off on November 16. On the first day of the media day, various car companies have brought their own strong new car lineups. From the current point of view, a total of more than 100 new cars have been launched one after another, including some blockbuster global premieres, such as FAW Toyota’s new (|), Aston Martin DB11 Volante 70th Anniversary Special Edition, etc. Without further ado, let’s enter this article to see the new cars unveiled at this year’s auto show.

| Guangzhou Auto Show debut/listing of new cars summary navigation |

| exhibition hall |

blockbuster model |

Portal |

| 1.1 |

Mid-term facelift Kia KX5, Kia SP concept car, Changan Mazda CX-8 |

first page |

| 2.1 |

Mid-term facelift Corregia, Qoros 3 EV, Qoros 5 Smart Cloud Connected Edition, Qoros 5 FCV, new Cadillac CT6 |

first page |

| 1.2 |

Dongfeng Honda Xiangyu, BAIC New Energy EX3, BAIC Saab Zhidao, Sway G01 F version model, Pentium T77, new Dongfeng Fengshen AX3, Dongfeng Fengshen E70 500 |

second page |

| 2.2 |

GAC Trumpchi GM6, GAC New Energy Aion S, Concept VE 1 |

Page Three |

| 3.1 |

MG ZS pure electric, SAIC Datong RG10, Datong G50, Changan CS85, Changan New Energy Yidong ET |

Page Four |

| 3.2 |

Luxgen U5 EV, Jianghuai Ruifeng S4, Auchan COSMOS (Keshang), Zotye Z500EV Pro |

Page 5 and Page 6 |

| 4.1 |

New Corolla, New Leiling, New Peugeot 508L, New Asian Dragon, BMW 1 Series Seat Edition M Sport, New BMW X5, Hyundai New Shengda |

Page 7 and Page 8 |

| 4.2 |

Qichen T60, Haval H4 Zhilian Edition, Haval H6 Champion Edition, Euler iQ High Battery Life Edition, Tang EV, Tang Five-Seat Edition |

Page 9 and Page 10 |

| 5.1 |

New Mercedes-Benz C-Class, New AMG C-Class, AMG GT four-door version, Hongqi HS7 |

Page 11 |

| 5.2 |

Brilliance Renault Gold Cup View, Lingkun EV, New Malibu XL, Chevrolet Monza, Chevrolet FNR-CarryAll Concept Car |

Page 11 |

| 6.1 |

Golf · Jialu, new Tiguan L, new Tiguan L R-Line, Tiyue R-Line, new Touon, Weilan GTE, Audi’s new A6L, new Kodiak, Kodiak GT |

Page 12, Page 13 |

| 8.1 |

New Land Rover Discovery, New Land Rover Range Rover, New Land Rover Range Rover Sport, WEY P8 GT, VV5 Final Edition, New Ao Tiger, New Lion, Lexus New RC |

Page 14 |

| 9.3 |

Porsche’s new Cayenne, Maserati Levante GTS, Aston Martin DB11 Volante 70th Anniversary Special Edition |

Page 15 |

| 10.3 |

Nezha N01, Nezha 03 |

Page 15 |

| 12.2 |

Nanjing IVECO Daily 8AT |

Page 15 |

★ Hall 1.1: Dongfeng Yueda Kia, Dongfeng Fengxing, Mazda

First launch: mid-term facelift Kia KX5

At this year’s Guangzhou Auto Show, Dongfeng Yueda Kia’s new KX5 was officially released. The new car maintains the same design style as the new Kia SPORTAGE launched at the 2018 Paris Auto Show, and the design language is more sporty.

In terms of appearance, the new KX5 has been mainly optimized for appearance. The tiger-roaring upper grille has been retained on the new car, but the internal middle net has been changed to a dense T-shaped triangle structure. The size of the lower grille and fog light trim has become larger, emphasizing the sense of momentum in the front of the car. Four LED light sources are integrated into the headlight cavity.

The interior design and power information have not been officially announced yet, but the official said that the new car will be equipped with a new infotainment system in cooperation with Tencent and Baidu. It is expected that its power will continue to use the 1.6T and 2.0L engines of the current model, of which the 1.6T model is matched with the 7DCT dual-clutch transmission, and the 2.0L model is matched with the 6AT automatic transmission. The 1.6T model has two-wheel drive and four-wheel drive.

Launch: Kia SP concept car

At this year’s Guangzhou Auto Show, the Kia SP concept car was officially unveiled in China. The Kia SP concept car is a brand-new SUV released at the 2018 New Delhi Auto Show. According to foreign media reports, the car will be turned into a brand-new small SUV.

The Kia SP concept car weakens the family-style tiger roaring grille. The middle net is outlined with silver decoration and extends to the light groups on both sides, making the front face feel more integrated and imposing. The light group shape is sharp, and the roof is also integrated with LED light strips, making the new car look more personalized.

In terms of power, the official has not disclosed more information for the time being. The appearance at the domestic auto show this time, it is speculated that the car is expected to be introduced into the domestic market in the future.

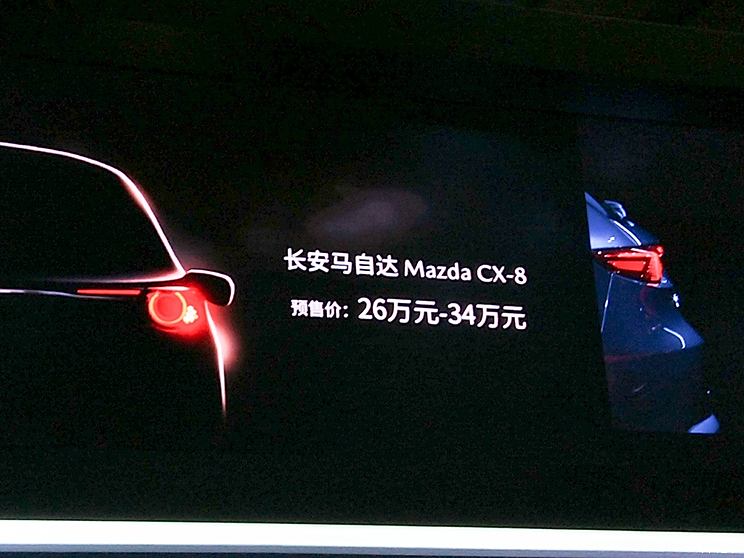

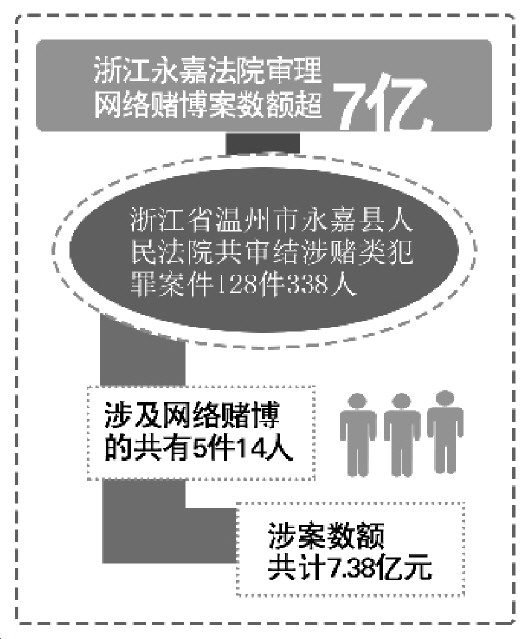

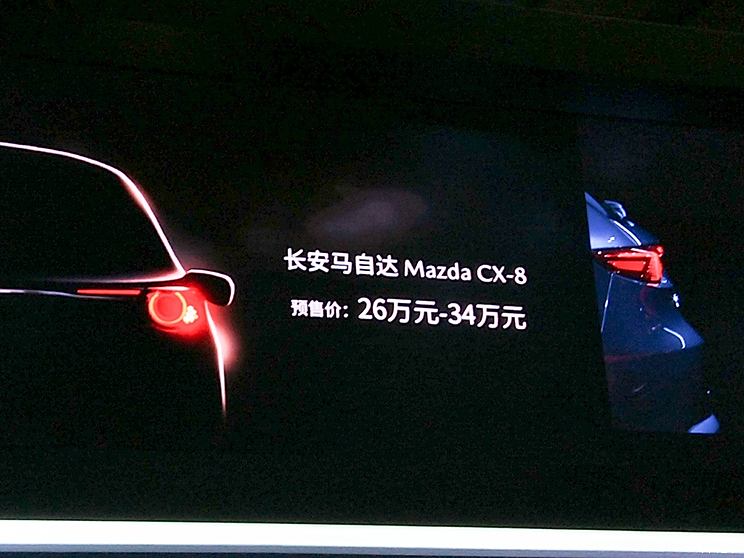

Pre-sale: Changan Mazda CX-8

At the 2018 Guangzhou Auto Show, we welcomed the interior debut of the Mazda CX-8.At the same time, the official announced that its pre-sale price range is 26-340,000 yuan.The new car will be officially launched in December. The Changan Mazda CX-8 was officially unveiled as early as this year’s Chengdu Auto Show. The whole series adopts a 7-seat layout, and the power is replaced with a 2.5L naturally aspirated engine.

The new car retains the appearance of the overseas version of the model, and the style is similar to the new CX-5 and new CX-9 models, which is the latest generation of Soul design style. In terms of size, the length, width and height of the new car are 4955/1842/1733mm respectively, and the wheelbase is 2930mm. Compared with the Japanese version, there are only subtle differences in length and width.

The interior of the domestic CX-8 also follows the design of the Japanese version, only switching from the right rudder layout to the left rudder, and has a high degree of similarity with the new CX-5: the overall center console is simple and layered, and is equipped with a floating center control screen, a multi-function steering wheel, a key start, and electronic parking.

In terms of power, the domestic CX-8 is equipped with a 2.5L Chuangchi Blue Sky inline four-cylinder naturally aspirated engine with a maximum power of 192 horsepower. The transmission system is expected to match a 6-speed manual transmission.

★ Hall 2.1: Dongfeng Renault, Qoros, DS

First launch: mid-term facelift Corregia

Dongfeng Renault released the new Corregia at the just-opened Guangzhou Auto Show. Compared with the current model, the new car changes mainly focus on the details. The appearance has been adjusted for the front and rear bumpers, and the internal configuration has also been upgraded to a certain extent.

外观方面,新车主要针对车头部分进行了一些调整,在现款车型基础之上,新车换装了全新的梯形下部进气口,原有的雾灯被取消,变成了封死的黑色饰板(高配车型带有镀铬饰条),前大灯组采用全LED光源。车尾部分,新车同样仅针对保险杠造型进行了修改,牌照安装位凹槽处的轮廓变为了梯形,两侧后雾灯的形状也更加细长,配以更宽更扁的底部银色饰板,使得车辆尾部看上去更加宽阔。尺寸方面,新车的长宽高分别为4508/1836/1610mm,轴距为2645mm,换装18英寸钻石切割轮圈。

内饰方面相比现款车型,新车也没有发生明显的改变。新款科雷嘉增加EASY LINK智能互联系统、CLEAN AIR PM2.5空气净化功能,并且主要针对后排配置进行升级,包括增加后排空调出风口及USB接口等实用配置。动力方面,新款科雷嘉或将沿用现有的1.2T和2.0L两款发动机,最大功率分别为117马力和150马力,传动系统方面或将继续匹配6速手动和CVT无级变速箱。

首发:观致3 EV

在本届广州车展上,观致 3纯电动版正式上市销售。新车与当前在售中的观致3燃油版设计相符,除了将前中网更改为全封闭式之外,其它细节变化不大。

新车在设计上与现款观致3燃油版造型基本保持一致,但将前中网更换为全封闭式,同时也取消了前雾灯。在车身尺寸方面,新车长宽高分别为4633/1839/1510mm,同时轴距达到了2702mm,整备质量为1680kg,并提供了两种轮胎规格,分别为215/55 R18和215/60 R17。另观致3纯电动版会根据销售车型的高低配不同,提供三种样式的选装轮圈以及侧方和后方包围。

In terms of interior, referring to the previous photos of the exploration hall, the Qoros 3 pure electric version is basically the same as the ordinary version in terms of design and layout, but the new car should be equipped with a large LCD instrument panel and an electronic knob stopper. In the central control part, the new car is not equipped with a large LCD screen.

In terms of power, the new car is equipped with a motor with a peak output power of 217 horsepower (about 160 kW), a maximum speed of 160 km/h, and a set of ternary lithium batteries, with a comprehensive cruising range of up to 450 kilometers.

First Release: Qoros 5 Smart Cloud Connected Edition

At this year’s Guangzhou Auto Show, the first Qoros 5 SUV with Zebra system, the Smart Cloud Connected Edition, was officially released.

The appearance and interior design of the new Qoros 5 SUV have not changed much. The body size is 4600/1869/1676mm in length, width and height, and the wheelbase is 2710mm. In terms of configuration, the key upgrade of the new car is to be equipped with the Zebra intelligent network system, which has improved riding comfort and technology configuration, and will provide consumers with smarter connected travel solutions.

In terms of power, the new Qoros 5 SUV continues to be powered by a 1.6T turbocharged engine, with a maximum power of 150 horsepower and a peak torque of 230N · m. It also offers six-speed manual and six-speed dual-clutch transmissions for consumers to choose from.

Launch: Qoros 5 FCV

At the just-opened 2018 Guangzhou Auto Show, a fuel cell vehicle to demonstrate future research and development directions – the Qoros 5 FCV (hydrogen fuel cell) model was officially unveiled.

In terms of appearance, we noticed that the side of the car body is pasted with Fuel Cell Vehicle (fuel cell model) and Zero Emissions (zero emissions) body latte. Compared with the fuel version, the appearance design of the new model has not changed much, and the overall design elements use the family language. But the new car has a new set of wheels, which looks more technological.

In terms of power, it is expected that this new car will use fuel cells as a power system, and the specific technical information has yet to be officially disclosed.

Launch: New Cadillac CT6

On November 15, the new Cadillac CT6 was officially unveiled during the eve of the 2018 Guangzhou Auto Show. The new model unveiled this time is a mid-term facelift of the current CT6. In addition to some upgrades in design and configuration, the new car provides a new 2.0T turbo engine and 3.0T twin turbo engine in terms of power.

The exterior of the new Cadillac CT6 still maintains the "diamond-cut" sharp overall style, but adopts more radical design elements in parts. The headlights retain the iconic "tear-eye" daytime running lights, and the headlights have become flatter.

The rear of the car still maintains its previous solemn temperament, and the change of the L-shaped taillights also adds some details and vitality to the rear of the car. In terms of size, the length, width and height of the new car are 5223/1879/1492mm, the wheelbase is 3109mm, and the body length has increased. The tire specifications are divided into 235/50 R18 and 245/45 R19, and there are more options for wheel rim styles.

In terms of the interior, the overall design layout of the new car is not much different from the current model. The most obvious place is the replacement of the electronic gear lever, and the surrounding layout has also been adjusted, including the new knob control. In terms of configuration, the new car will have a 10.2-inch central control screen, a 12.3-inch full LCD digital instrument panel, a carbon fiber decorative panel, and a sensor trunk.

In terms of power, the new Cadillac CT6 will offer a new 2.0T turbo engine and a 3.0T twin turbo engine. The 2.0T engine, which is the main force of sales, has a wider peak torque platform than the current 2.0T engine, and supports closed-cylinder technology. According to the information obtained so far, the new 2.0T engine has a maximum power of 234 horsepower (172kW), which is a certain decrease compared to the current 2.0T engine (276 horsepower). In terms of transmission system, the new car will be matched with a new 10-speed automatic transmission.